Alliance Partner News – ForneyVault and HaulHub

November 30, 2023Embracing the Digital Evolution in Construction: HaulHub and the AASHTOWare Alliance

HaulHub is honored to work with state transportation agencies across the country as they look to modernize their construction processes and provide tools to their construction inspection teams that are simple, scaleable, and integrate seamlessly into the AASHTOWare suite of products. This innovative approach is reshaping how DOTs across the nation collaborate with the private sector, particularly in digitizing asphalt, concrete, and aggregate tickets.

The DOT E-ticketing™ portal is a testament to the seamless integration of digital workflows, where DOTs find a robust platform to conduct business with their private sector partners efficiently. This system not only streamlines operations but also embodies the spirit of innovation and collaboration critical in the modern construction landscape.

Recently, West Virginia DOT has been at the forefront of expanding material capabilities within the portal, including precast and plastic pipe and rebar. This pioneering move indicates the evolving needs in construction and HaulHub’s commitment to meeting these needs with advanced technological solutions.

HaulHub’s partnership with DOTs extends beyond just providing a platform; it’s a collaborative journey. Regular weekly meetings are a cornerstone of this relationship, ensuring that the deployment and integration of digital tools across the construction materials supply chain are seamless and effective.

The recent announcement of Advanced Digital Construction Management Systems (ADCMS) (https://highways.dot.gov/newsroom/biden-harris-administration-announces-34-million-grants-10-states-advanced-digital) grants has brought a new wave of excitement and is set to accelerate the journey to digital project delivery. These grants, totaling $34 million to 10 states, are part of the Bipartisan Infrastructure Law and aim to promote digital construction practices and allow DOTs to leverage real-time data to improve project delivery. This financial boost will further empower DOTs to integrate additional elements of the construction process into their AASHTOWare systems, aligning with the broader goals of FHWA’s BIM for Infrastructure Roadmap (https://www.fhwa.dot.gov/publications/research/infrastructure/pavements/21064/index.cfm?_gl=1*rtqy9f*_ga*MTQzNjA2MzExMC4xNTg4MTc2NTMz*_ga_VW1SFWJKBB*MTcwMDI1OTE0Ny4zNC4xLjE3MDAyNTkxNzIuMC4wLjA.).

A significant innovation in this digital journey is the AASHTOWare OpenAPI. States like Nebraska are harnessing this framework to develop and deploy additional innovations, thereby building upon their existing digital materials capabilities. This approach not only enhances internal processes but also allows for interconnectivity with other systems, like asset management tools, providing a more comprehensive analysis of pavements and other materials by tying together different datasets and tools that leverage the AASHTOWare OpenAPI.

HaulHub’s Alliance with AASHTOWare is not just a technological alliance; it’s a shared vision for a digitally empowered future in construction. This collaboration is setting new standards in the industry, driving efficiency, enhancing transparency, and fostering a culture of innovation that resonates throughout the national construction landscape.

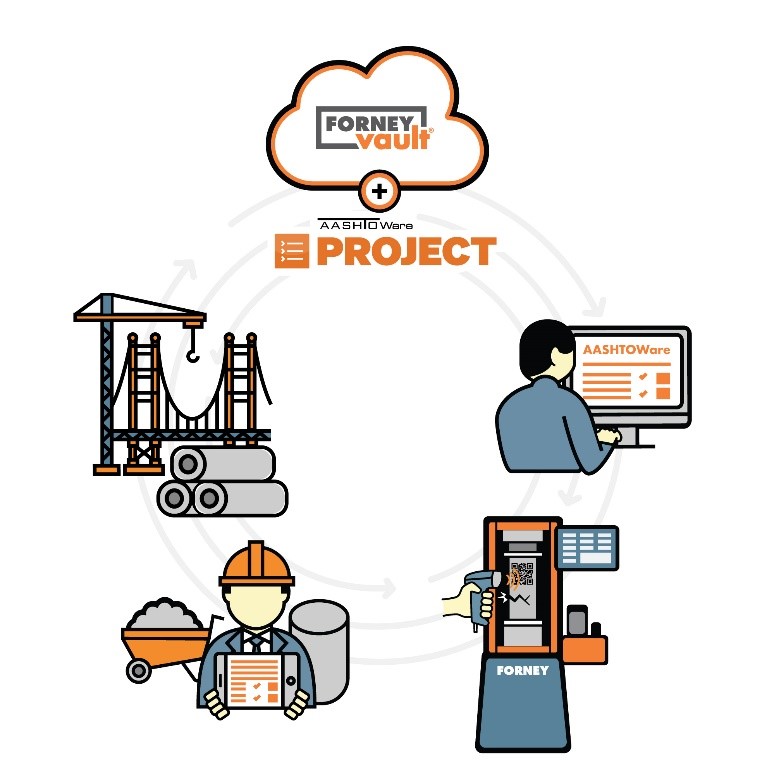

3 Benefits of AASHTOWare Project + ForneyVault for DOT Agencies

ForneyVault construction materials testing (CMT) software is available to all department of transportation (DOT) agencies through an interface with AASHTOWare Project. Here’s how it works and why it’s beneficial.

At the beginning of the CMT workflow, technicians on the job site collect wet concrete properties and capture all that data in the AASHTOWare Project system. With ForneyVault, this information is put to work across the remainder of the project:

- Before Strength Testing: A unique identifier is assigned to every specimen and tied to sample and wet concrete data. A label with this identifier can be applied to each specimen.

- Testing: Technicians scan the label at the machine, preloading specimen and test data, preventing invalid testing parameters. Specimen measurements are also entered at the machine.

- After the Test: Test data automatically syncs to AASHTOWare Project.

This interface has already benefited DOT Agencies. Tim Krason, PCC Materials & Tests Manager at Nebraska DOT, said: “It has sped it up to where we think it has cut our time in half.”

Here’s why this is beneficial:

#1. Eliminate Manual Data Entry & the Clipboard

Technicians can complete tasks faster with minimal human error. Data automatically flows between the two systems and the test machine, eliminating manual data collection and repetitive manual data entry.

#2. Access Verifiable, Unalterable Data

Sample and testing data is secure, better informing material approvals, qualifications, and more, and streamlining the entire material sample lifecycle.

#3. Promote Transparency

Automatic testing procedures enhance transparency, driving more positive outcomes for Agencies and partner labs.

The CMT workflow in the lab is a small yet significant part of a project. ForneyVault automates this testing – then seamlessly connects it with the rest of the project in AASHTOWare Project.